Enduring Foundations: The Life Cycle of Concrete and Emerging Alternatives

Concrete has shaped nearly every corner of the built environment; from modern skylines to the immersive plazas and pathways of themed destinations. Its strength, accessibility, and familiarity have made it the foundation of contemporary construction. But as the conversation around sustainability grows louder, so does awareness of concrete’s environmental and human impacts. From the resources it requires to the systems it supports, every stage of its life cycle matters.

In this edition of CASTO Corner, we explore the evolving story of concrete; its traditional challenges, the lessons it offers from history, and the material alternatives that could define the next generation of construction.

Concrete’s Conventional Cycle

Traditional Portland cement–based concrete has been the global standard for more than a century. Its performance and predictability make it the material of choice for themed environments, where structure and surface must work seamlessly together. Yet the process behind it carries significant environmental weight. Producing cement accounts for nearly eight percent of global carbon

emissions, driven primarily by the energy-intensive process of heating limestone and clay to form clinker; the essential binder that gives concrete its strength.

Beyond carbon, the extraction of raw materials impacts communities and ecosystems. Large-scale quarrying disturbs local environments, while transportation and water use add to its footprint. Still, its reliability keeps it indispensable across industries. The challenge lies not in abandoning concrete, but in refining it; finding methods that retain its durability while reducing its costs to people and the planet.

Health and Human Impact

The life cycle of concrete isn’t just an environmental concern, it’s also a matter of health. Workers exposed to concrete dust during cutting, grinding, or demolition face risks associated with respirable crystalline silica, which the Occupational Safety and Health Administration (OSHA) identifies as a cause of lung disease and silicosis. In addition, some supplementary materials used in low-carbon concrete, such as fly ash, can contain trace metals that raise long-term safety questions during handling.

Protecting those who work with these materials daily means prioritizing dust control, proper ventilation, and safe material sourcing. True sustainability includes human well-being, and in themed construction, where artistry and craft meet industry, that means caring for both the environment and the people shaping it.

Sources:

Occupational Safety and Health Administration (OSHA), Silica, Crystalline – Overview and Health Effects, 2023.

Dust Safety Science, Managing Concrete Dust Exposure in the Construction Industry, 2024.

Concrete Captain, Understanding the Health Effects of Cement Dust Exposure, 2023.

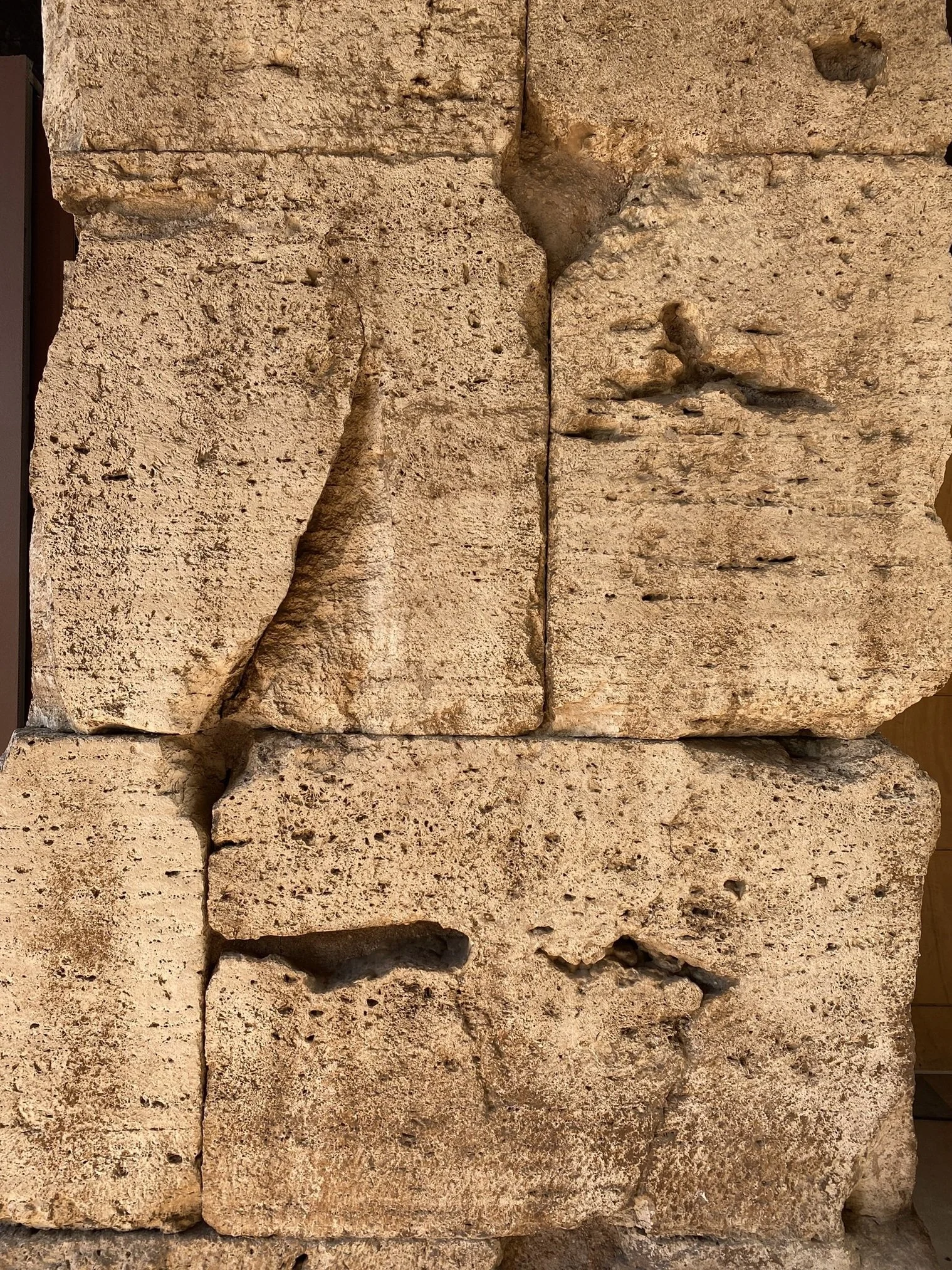

Lessons from the Past: Roman Concrete

The Romans built for permanence. Their concrete, made from lime, volcanic ash, and seawater, has endured for over two millennia, sometimes strengthening with age. Researchers at MIT and GeoscienceWorld found that Roman concrete’s self-healing properties stem from quicklime inclusions that react with water over time, forming binding crystals that repair cracks naturally.

This longevity challenges the modern mindset of “build fast, replace often.” For today’s designers, durability is one of the most sustainable traits a material can possess. When themed environments are expected to perform for decades under heavy use, thinking like the Romans; designing for time, not just performance, becomes a lesson in both craft and conservation.

Sources:

MIT News, Riddle Solved: Why Roman Concrete Is So Durable, 2023.

GeoscienceWorld, Unlocking the Secrets of Al-Tobermorite in Roman Seawater Concrete, 2013.

Concrete Alternatives and Material Adjustments

Modern research is expanding the definition of what concrete can be. By blending cement with supplementary materials like fly ash, slag, or calcined clays, manufacturers are lowering embodied carbon while maintaining comparable strength. Companies such as CarbonCure and Eco Material Technologies are capturing or mineralizing CO₂ directly into the mix, transforming a source of emissions into part of the solution.

Still, no alternative is without trade-offs. Low-clinker cements may cure more slowly, altering project sequencing. High-reactivity blends can behave unpredictably in heat or humidity. For themed environments, where surface detailing and overlay systems rely on precise curing and moisture behavior, understanding how each mix interacts with finishes is essential. The path to lower-impact concrete is not only technological but also practical: it requires testing, coordination, and field awareness at every stage of the process.

Sources:

Eco Material Technologies, Carbon Reduction Through Pozzolanic Cement Blends, 2024.

CarbonCure Technologies, Embedding Carbon Mineralization in Concrete Production, 2024.

International Energy Agency (IEA), Cement and Concrete – Analysis, 2024.

Balancing Timelines and Trade-Offs

New concrete systems introduce both opportunities and challenges in construction workflows. Many sustainable alternatives extend life span and reduce long-term maintenance, yet they also require new curing schedules, finishing techniques, and supplier coordination.

Key considerations for project teams include:

Supply and availability: Low-carbon blends may not yet be regionally accessible, requiring early procurement planning.

Performance and compatibility: Adjusted curing or moisture profiles can impact overlays, coatings, or scenic finishes.

Crew adaptation: Field teams may need retraining to handle different workability or set times.

Lifecycle benefit: While short-term adjustments can affect schedules, the extended durability and reduced maintenance often outweigh initial challenges.

By acknowledging these realities early, project teams can make informed decisions that balance constructability with environmental responsibility.

Sources:

Global Cement and Concrete Association (GCCA), Cement Industry Net Zero Progress Report 2025.

World Economic Forum, Sustainable Concrete Is Possible – Here Are Four Examples, 2024.

Looking Forward

At CASTO Creative, we continue to explore material approaches that support both constructability and long-term environmental awareness. The future of concrete isn’t about replacement, it’s about refinement. Each advancement, from improved mix design to carbon reduction, helps balance the material’s enduring utility with environmental responsibility.

As material science and construction methods continue to evolve, the role of design professionals will be to bridge creativity and accountability; building structures that perform beautifully and endure responsibly. The life cycle of concrete is changing, and so is our understanding of what it means to build with purpose.

Sources:

International Energy Agency (IEA), Cement and Concrete – Analysis, 2024.

World Economic Forum, Sustainable Concrete Is Possible – Here Are Four Examples, 2024.