The Rise of Modular Construction in Themed Environments

Why Prefabrication is Reshaping the Future of Immersive Design

In the world of themed construction, speed, storytelling, and precision have always been a balancing act. But as immersive environments become more complex — and timelines more compressed — a new approach is taking center stage: modular construction.

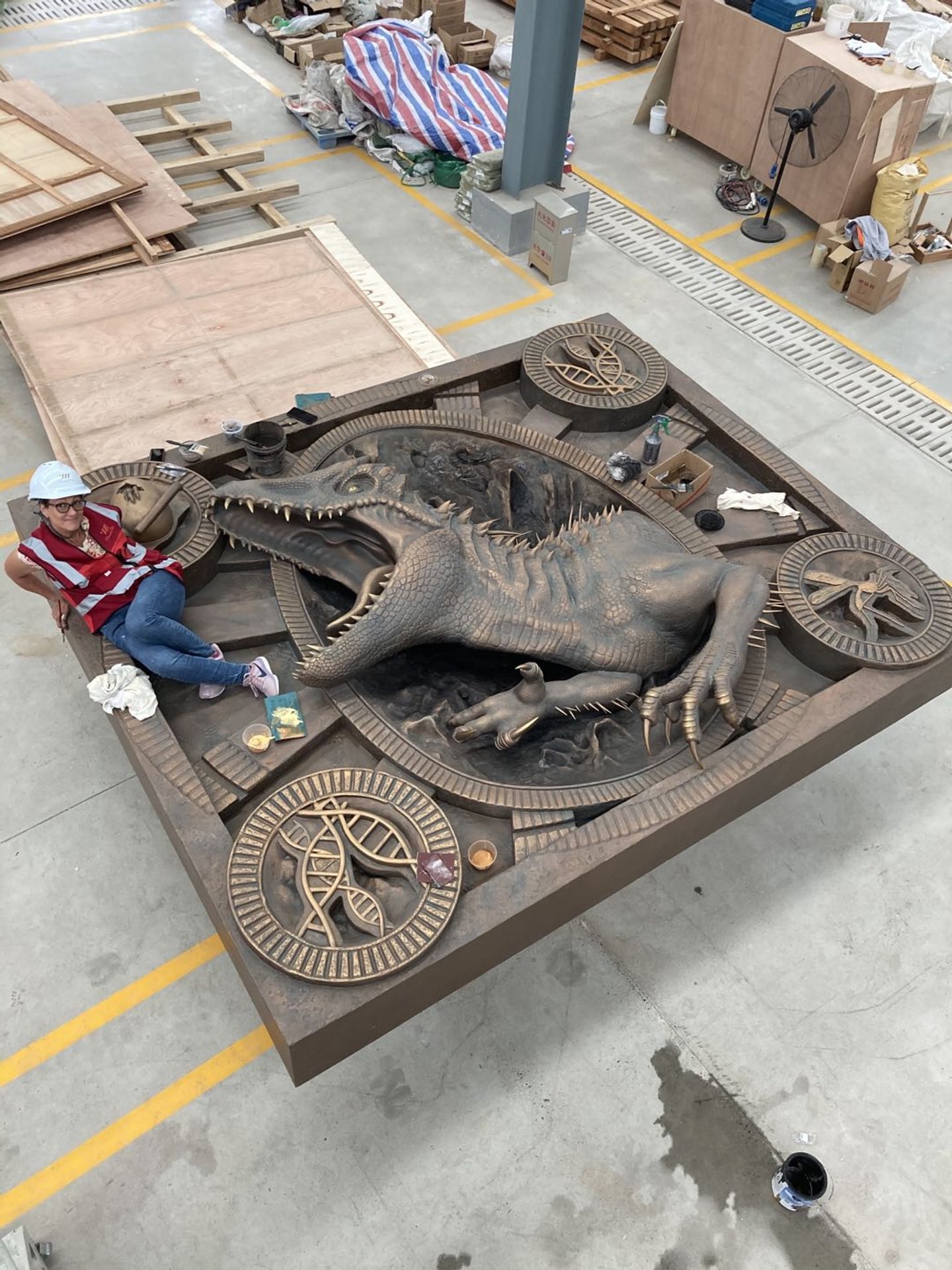

At CASTO, we’ve seen firsthand how modular strategies — including panelized scenic elements, off-site finish integration, and prefabricated specialty components — are transforming the way projects are delivered. This blogpost explores how modular methods are redefining constructability in the themed entertainment industry, with insights drawn from Universal Epic Universe, Disney Parks, and projects like Universal Studios Beijing.

What Is Modular Construction in Themed Work?

In traditional construction, themed finishes are often sculpted, painted, and detailed entirely on-site — which can lead to weather delays, sequencing conflicts, and costly rework.

Modular construction flips the script by relocating key parts of the process off-site:

Pre-sculpted rockwork or faux wood panel systems

Panelized scenic walls (with integrated steel, mesh, and coatings)

Molded concrete hardscape tiles or stamped pavers

Pre-painted thematic elements with mounting systems

Plug-and-play scenic units with embedded AV, lighting, or FX

The result? More control. Less chaos.

Why It’s Gaining Momentum

According to Matthew Casto, CEO of CASTO and longtime themed construction expert:

Modular construction isn’t about cutting corners. It’s about cutting risk.

You’re taking creativity and giving it the structure to succeed under pressure — without sacrificing detail or durability.

Here’s why modular is on the rise:

Speed to Market: Components can be built months in advance and shipped for quick install.

Labor Strategy: Off-site work allows teams to bypass regional labor shortages.

Cost Efficiency: Reduces on-site hours, accelerates dry-in schedules, and avoids weather delays.

Consistent Quality: Controlled environments ensure better color control, finishes, and adhesion rates.

Case Study: Modular Thinking at Epic Universe & Beijing

Members at CASTO have supported multiple modular-ready projects by producing or reviewing:

Sample panels and mockups off-site for finish approvals

Prefabricated hardscape elements like stamped plaza panels or polished terrazzo slabs

Painted scenic finishes that integrate directly into architectural frames or vertical steel

Training for install crews to handle bolting, patching, and on-site blending

In Universal Studios Beijing’s Transformers Metrobase zone, sculpted crystal towers and carved metallic walls were fabricated as geometric, modular systems.

At Epic Universe, we’ve seen modular framing and coating systems used for themed towers and gateway elements — all built for rapid install between complex show systems.

Behind the Scenes: How Modular Construction Actually Works

Modular construction may look effortless from the outside, but behind the scenes it’s a highly choreographed process. Here’s a breakdown of what goes into bringing a prefabricated themed element to life:

1. Pre-Production: Setting the Stage

Define performance, aesthetic, and structural goals

Develop detailed design documents (creative, technical, engineering)

Qualify vendors via tendering, sample reviews, site inspections

Finalize shop drawings, means & methods, install strategy, and safety protocols

2. Manufacturing: Where Art Meets Engineering

Materials are sourced, molded, cast, and finished based on system needs

High-volume elements are streamlined; artistic custom parts require greater coordination

Ongoing feedback between field teams and shops ensures alignment and adaptation

3. Transportation & Storage: Precision in Motion

Prefabricated pieces are packaged and moved to site — with attention to fragility, scale, and storage environment

Some materials need protection from climate; others require custom loading equipment

Planning for lift points, access zones, and laydown space is essential

4. Installation: On-Site Integration

Involves hoisting, mounting, anchoring, and patching of each element

Adjustments are common; sometimes new parts are remade due to field condition changes

Accuracy is critical — even small deviations can disrupt theming or functionality

5. Finishing: Seamless Completion

Includes joint sealing, touch-ups, coatings, and surface preparation

Moisture and pH testing ensure proper sealer or paint adhesion

Final protective measures keep the finish intact before handoff

The Key to Themed Modular Success? Constructability.

Modular scenic elements — whether panelized or fully prefabricated — still need to:

Be paintable, patchable, and blendable on site

Withstand weather, moisture, and building movement

Deliver seamless integration with architecture, utilities, and show elements

Be maintainable and replaceable with minimal disruption

That’s where CASTO’s constructability reviews come in — helping clients understand where modular makes sense and where it needs support.

From reviewing panel thickness to prepping patch kits to developing field reference samples, we guide projects through every stage of the prefab lifecycle.

Coordination Is Everything

Modular construction doesn’t eliminate complexity — it reshapes it. Here’s where Creative Design Reviews and vendor collaboration are critical:

Vendor Alignment: Partners need coordinated elevations, sections, and tolerances early

Material Coordination: Collaborating with suppliers ensures coatings and textures match seamlessly

Design Documents: Mock-up binders and build orders that outline sequencing, tolerances, or anchoring methods

“We’ve worked on projects where a rock face, a themed bench, and a signage mount all had to hit the same anchor point within 2 millimeters,” says Matthew. “Without a modular mindset and mock-up prep, that’s impossible.”

Benefits vs. Limitations

Advantages

Better schedule and cost control

Higher quality outcomes in controlled environments

Reduced on-site labor hours and weather exposure

Safer work conditions and less jobsite congestion

Sustainable production with less waste and pollution

Scalable production of both repeatable parts and artistic custom work

Challenges

Larger pieces may be expensive to ship or limited by transit regulations

Modular design requires early decision-making and finalization

High up-front investment in molds and shop setup

Skilled labor still needed for install, patching, and blending

On-site storage must be carefully coordinated

Site deviations may require rework, adding time and cost

Final Thought

Modular construction doesn’t mean giving up artistry.

It means protecting it — with smarter planning, earlier reviews, and a holistic view of the entire lifecycle.

As our industry continues to evolve, prefabricated strategies will keep gaining ground — not because they’re trendy, but because they’re practical, scalable, and deeply effective.

At CASTO, we’re proud to keep building the bridge between imagination and installation — whether it’s poured in place or shipped on a truck.